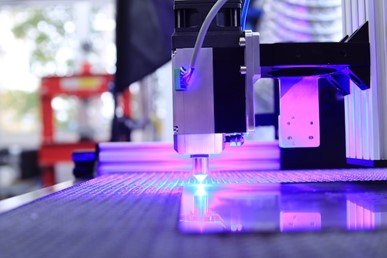

When Charles Hull invented 3D printing in 1984, he was trying to develop a machine to use UV lasers to engrave acrylic layers used to build a slew of everyday products.

Almost 40 years later, 3D printing has been an integral part of numerous medical breakthroughs and modern treatments. That’s because 3D printing in medicine offers designs specific to unique patient needs, can be fabricated quickly, and comes at a lower cost than most alternatives.

As early as the 1990s, 3D printing was used for such medical purposes as dental implants. Since then, scientists have produced 3D-printed jaws and prosthetic legs. Several medical labs designed their own 3D printers for very specific purposes, including replicating cartilage, stem cells, and materials that can function the same way as blood vessels and tissue.

And it’s just the beginning. John Kim UCLA explains how 3D printing technology has changed modern medicine — and why it will continue to do so.

Transformation

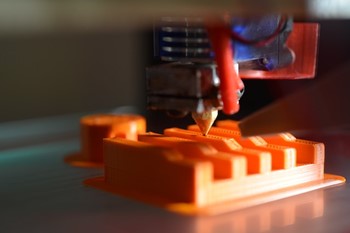

The healthcare industry was one of the first to take advantage of 3D printing technology, which takes a digital image and turns it into a solid, 3D object. The evolution has been swift and widely adaptable.

In many ways, 3D printing is uniquely suited for the medical field since it requires high customization and rapid progress in treatments. 3D printing for the medical field has become highly specialized. One company, Coapt, focuses on creating pattern recognition systems and additive manufacturing technology to build 3D printed and fully responsive prosthetic arms that meld into a patient’s biology.

By 2030, the 3D printed tools and molds industry is expected to be worth $21 billion.

Promising Uses in Medicine

Medical devices

3D printing is commonly used to create medical devices through software that produces on-demand instruments for surgery, surgical masks, and much more. 3D modeling has been used to produce ventilators when there has been a shortage in recent years.

For example, there have been over 10 million hearing aids generated from 3D printing — more than what is manufactured traditionally.

Implants and Prosthetics

One size fits all doesn’t quite work for prosthetics, so 3D printing has vastly changed the way they both function and feel. The technology also means customized prosthetics can be produced at a drastically lower cost than before.

Orthopedic medicine has long embraced this technology to replace injured or missing bones and joints, everything from skulls and hips to wrists and the small bones of the face and inner ear.

Bioprinting and Tissue Engineering

One of the more advanced uses of 3D printing is bioprinting, which uses a pipette guided by a computer to layer cells that are living on top of each other, leading to lab-made artificial living tissue. Such tissues can mimic organs, so they are especially beneficial in medical research and are emerging as alternatives to organ transplants.

Surgical Guides

3D printing helps create surgical guides that are highly patient-specific and used by surgeons to effectively plan and perform complex surgeries. 3D printing can take a patient’s anatomy and use it as a basis to suggest precise placement of instruments and devices, greatly improving outcomes while reducing operation times.