Technology has moved at unprecedented rates within the healthcare industry, with 113 hospitals nationwide boasting in-house 3D printing facilities as of 2019. Considering only three had such facilities in 2010, that’s quite a leap. And as each day goes by, John Myungjune Kim reports that more hospitals are hopping aboard this revolutionary technology bandwagon.

Simultaneously, the FDA has approved hundreds of 3D-printed products, thanks to research by the Pew Trust. Plus, the COVID-19 pandemic accelerated the use of the technology as institutions began relying on these printers to create PPE and medical devices.

Coupled with the fact that medical device manufacturers are increasingly utilizing 3D printing to reduce costs and meet supply demands, these developments are shaping the healthcare industry and its future. While they are not yet commonplace, hospitals and systems are certainly benefiting from existing technology and are excited about how it can transform clinical care in the coming years.

Impacts of 3D Printing

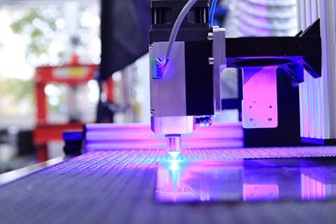

3D printers read digital blueprints, producing a three-dimensional solid object with ultraviolet light and filament.

The relatively simple inner workings of the equipment negate the need for heavy, costly machinery, accelerating product production. Already, the printers have cut production times for hearing aids by 85.71% (from one week to one day).

But the industry-changing technology has had many other impacts, too, including:

Building Anatomical Models

3D printers can craft incredibly accurate, intricately detailed anatomical models, giving surgeons the preparation they need to perform complex procedures and improve outcomes.

Researchers at the University of Virginia and Florida Atlantic University designed a robotic model of the human spine to enable surgeons to predict how interventions would work prior to surgery.

Upon studying the replica in 2022, results showed the system has 100% accuracy when determining the candidacy of implants in five different postures.

A 2020 study published in Academic Radiology reported that using replicas before the procedure reduced the surgical time by 62 minutes, saving $3,720 per case. According to a similar study in 2021, long surgeries decreased by 1.5 to 2.5 hours when 3D-printed models were utilized.

Fabricating Medical Equipment

Fabricating clamps, hemostats, forceps, and other medical devices is the most typical use for 3D printers in the sector. The biggest upside is the precise design modifications; they can be altered rapidly per surgeon feedback.

For instance, the recent worldwide shortage of ventilators was saved by the 3D-printed versions made by a group from Oregon Health & Science University. Utilizing the revolutionary technology allowed them to replicate the medical device for less than $10 of material.

Crafting Prosthetics and Implants

3D printing first found its medical usage with dental implants. However, the FDA has since approved the technology to create more complex implants and prosthetics.

A study published in 2021’s Journal of the American Academy of Orthopedic Surgeons showed that 3D printing impacted cartilage and bone restoration, boasting the potential to transform how practitioners treat musculoskeletal injuries.

Other experts note that the technology can enhance the function and fit of prosthetics. Since it’s become affordable and accessible, organizations have started creating limbs (particularly hands and arms) for individuals around the world.

Boosting the Number of Patients Treated

The efficiency and speed afforded by 3D technology ensures more people can access the treatment they need within a suitable timeframe (and at a more affordable cost).

By reducing time in surgery, decreasing costs, and lowering the risk of complications and errors, 3D printing streamlines medical professionals’ time to guarantee more patients are seen.

The Future of Bioprinting

As the evidence shows, 3D printing in healthcare has made leaps and bounds. But it certainly hasn’t finished growing.

Scientists and surgeons are hopeful that a UC-Berkeley-developed 3D printing process will make producing on-demand living blood vessels, body tissue, bones, and organs possible, allowing them to treat the over 100,000 people waiting for organ transplants in the US.

The Berkeley team put forward a bioprinting process that freezes and stacks cells simultaneously to ensure the organs and tissue survive until transplanted.

If 3D printing’s impacts weren’t already transformative, the bioprinting potential would completely revolutionize the field, granting overwhelmingly positive patient outcomes and boosting quality of life.